Original Prusa MMU3 upgrade kit (for MK4/MK3.9)

Original Prusa MMU3 upgrade kit (for MK4/MK3.9)

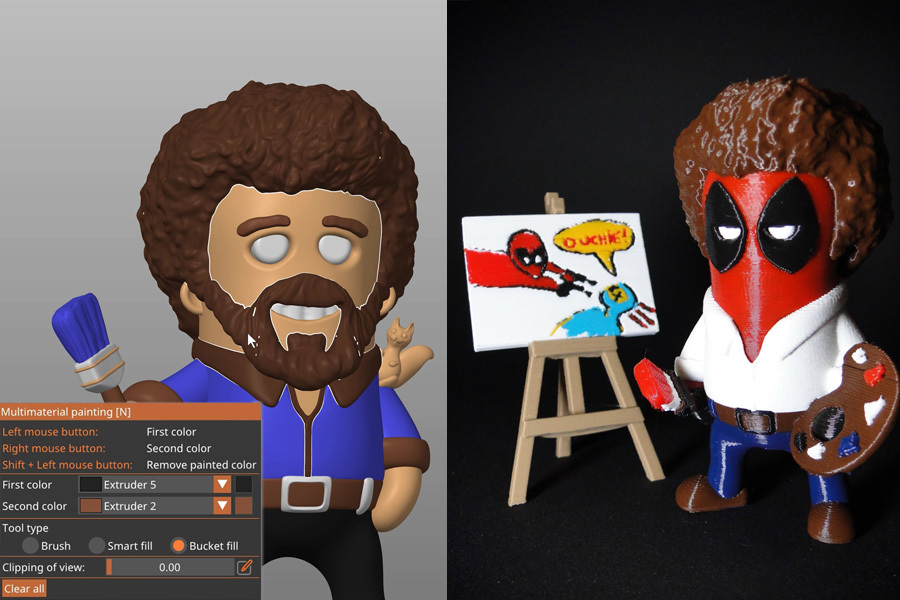

The Original Prusa MMU3 is the latest solution for printing with up to five filaments at the same time with high speed and low waste. As an add-on for the Original Prusa i3 MK3S+/MK3.5 and MK4, it enables automatic switching between loaded materials. MMU3 is fully supported in PrusaSlicer by an easy multi-material painting tool, and it offers efficient and filament-saving color printing to everybody.

This product is supplied as a kit - you must assemble it by yourself!

What is Multi Material Upgrade?

It’s exactly what it sounds like - it’s an optional add-on that allows your single-extruder printer to print with up to 5 colors (materials) at the same time. The MMU3 contains five filament insertion points. Load up to five colors of your choice, slice the object in PrusaSlicer and start the print. The system automatically selects filament using the selector, loads it into the extruder and the printer starts printing. When it’s time to change the color or material, it also happens automatically.

What's new in MMU3?

- Completely new firmware written from scratch

- Full two-way communication with the printer, Compatible with the MK3.9 and MK4

- LCD screen integration (status messages, real-time information, error codes)

- All plastic parts were redesigned with a focus on easier assembly and maintenance

- New metal parts to make the unit more robust and reliable

- Improved electronics

Efficient multi-color printing

Every time you switch filaments, you need to purge the previous material from the nozzle to prevent cross-contamination. There are various ways to do it and the MMU3 uses an efficient “wipe tower” - it’s a compact, partially hollow block next to the printed object where the filament is purged and the pressure in the nozzle is stabilized. All filament goes into one location and you don’t need to worry about bits of plastic piling around your printer.

We’re offering multiple ways how to save filament and reduce plastic waste - PrusaSlicer gives you options for “wipe into infill” (the printed object’s infill is used as a wipe tower) or you can use “wipe into object” where another object is used as a wipe tower - it will be very colorful but if you, e.g., need a functional part or you will paint it later, it’s a great way to reduce plastic waste to a minimum.

Main Features

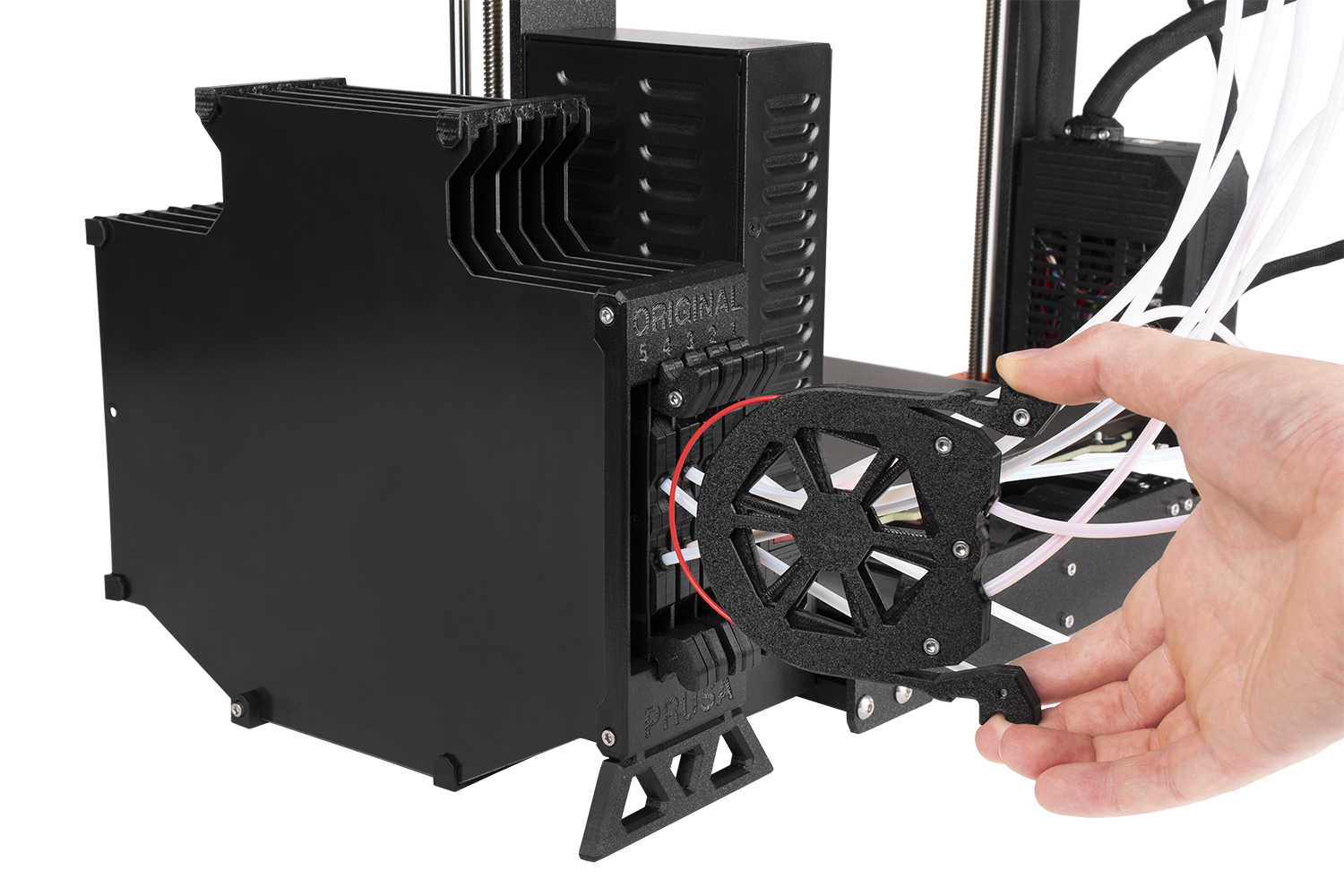

IMPROVED RELIABILITY AND MAINTENANCE

Main focus with MMU3 was to make the assembly, everyday operation and maintenance easier than before. With more reliable filament switching, improved communication between the MMU3 unit and the printer, and self-repair routines, the MMU3 can finish very complex objects with ease.

PRUSASLICER MAKES PRINTING EASY

COMPLETELY NEW MMU3 FIRMWARE

For the MMU3, prusa3d have rewritten the firmware completely from scratch, utilizing full two-way communication between the MMU3 unit and the printer. The MMU3 can diagnose and resolve various situations on its own and also displays detailed (and real-time) information on the LCD screen along with status messages and error descriptions.

DOZENS OF USEFUL LITTLE TWEAKS

Sample Prints

MMU3 package includes

- MMU electronics

- MMU motor set

- Printed parts or filament (2x 400g)

- SuperFINDA

- PTFE tubes and others

- Fasteners

- Spoolholders (5x)

- Buffer plates (6x)

- Extruder parts* (mechanical and printed)

Tools: (optional)

- 1.5 mm Allen key

- 2.0 mm Allen key

- 2.5 mm Allen key

- Needle-nose pliers

- Philips screwdriver PH2 (MK3S+ power terminals)

- Wrench 8 mm ( for QSM-M5 fittings)

Featured models

- Buzz Lightyear - Multi Color Print by ChelsCCT

- Generative Design F1 Brake caliper by amigodesigns

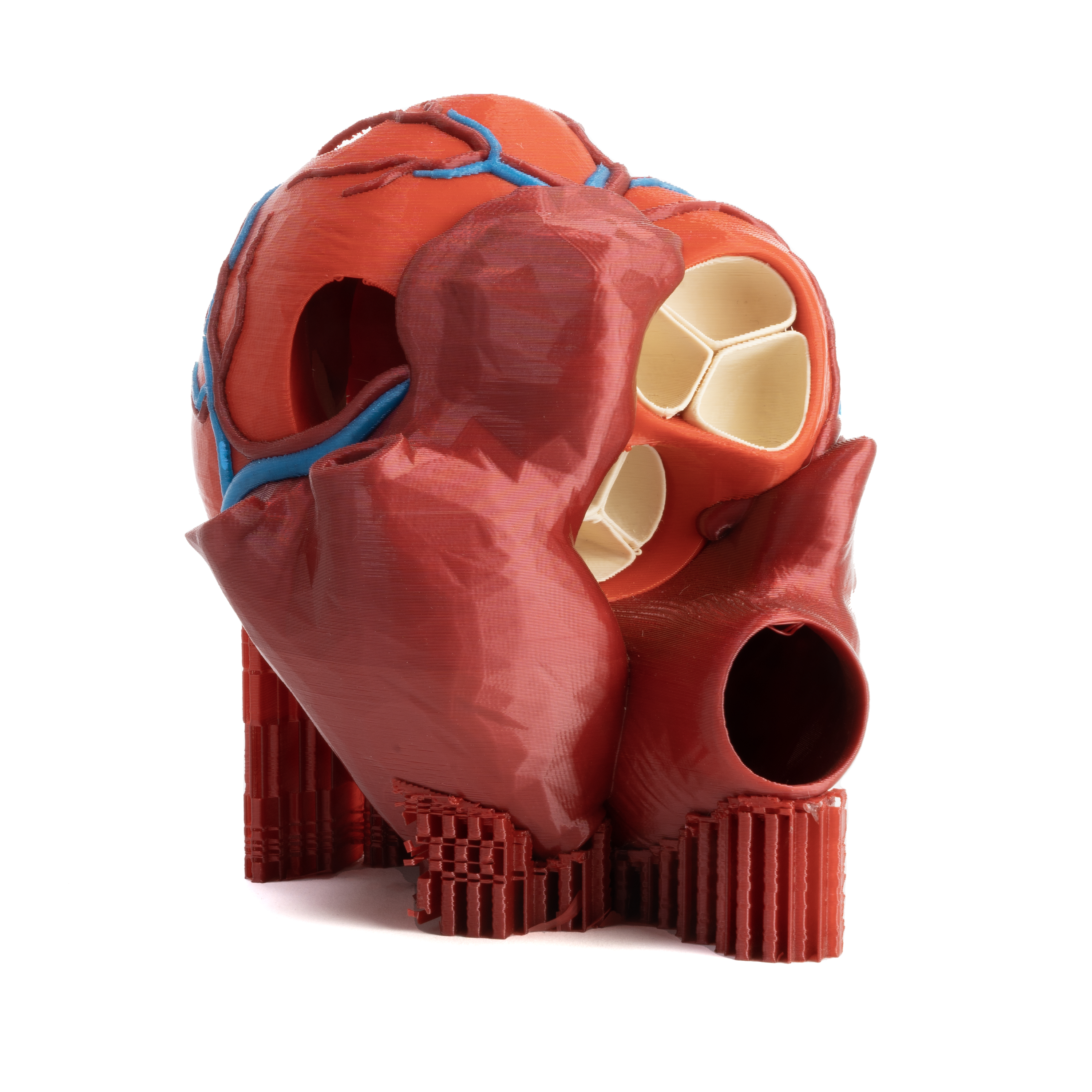

- Anatomic Heart (multi material) by Malte

- Bomb-Omb by Rob Beast

- Melting Rubik’s Cube (multi material) by Malte

- Lion Statue (multi-material) by Cipis

- Florence Cathedral , Italy by MiniWorld3

- Ferrari 246 F1 (multi-color) by Cipis

- Deadpool Bust by Eastman

- Lizard (multi-material remix) by Cipis